Understanding the Critical Role of Fire Hydrant Pipes in Fire Fighting

Fire hydrants are a common sight in our neighborhoods, but many people don’t realize how important they are for fighting fires. The pipes connected to these hydrants play a crucial role in keeping our communities safe.

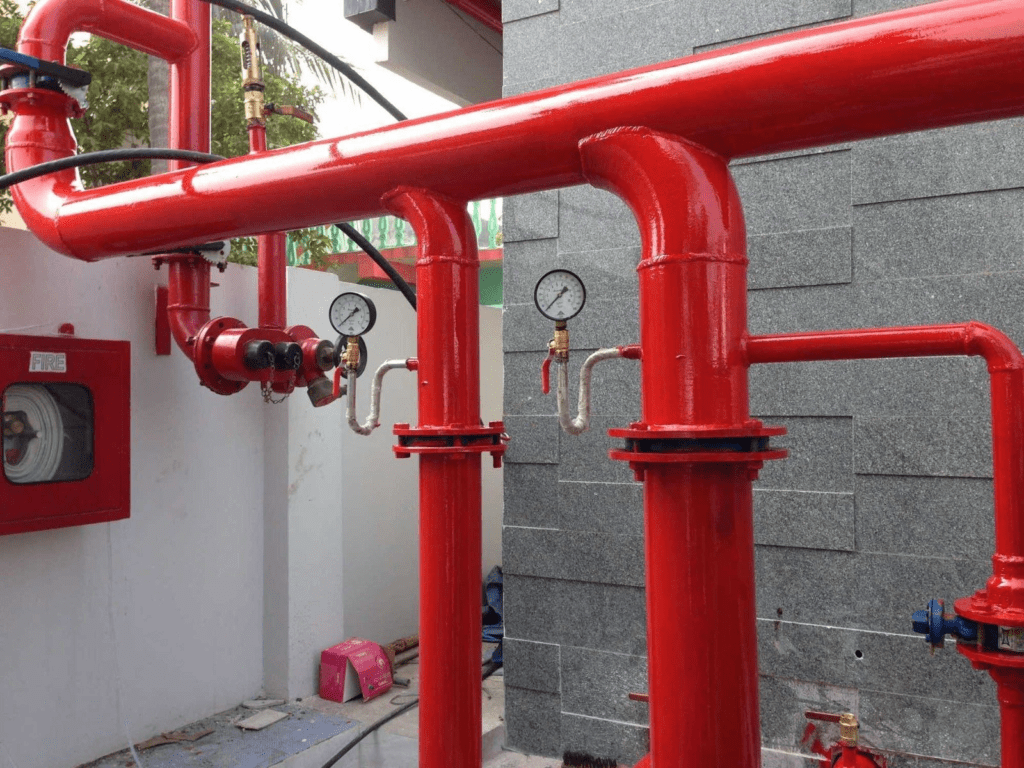

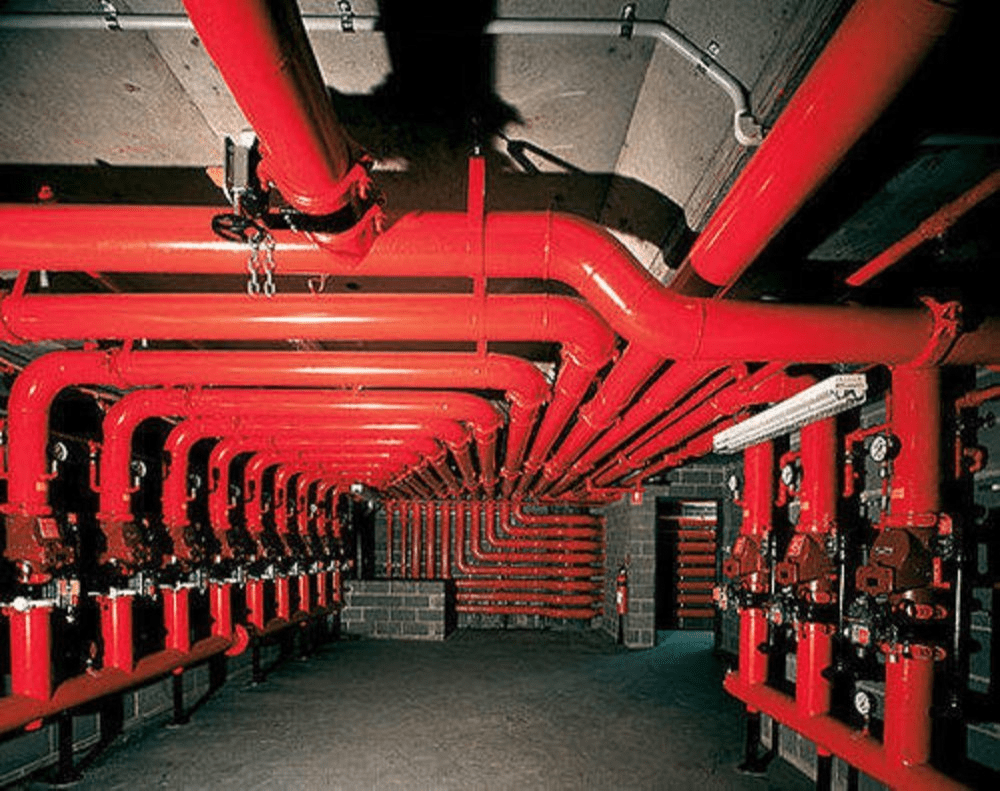

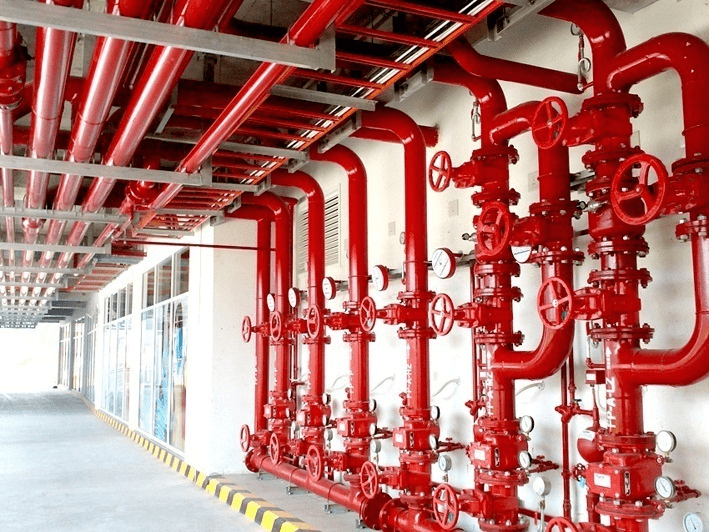

Fire hydrant systems are made up of more than just the red hydrants we see on street corners. They include a network of underground pipes that carry water to the hydrants. This network is a key part of a city’s fire-fighting infrastructure.

The main job of fire hydrant pipes is to supply water quickly and in large amounts when firefighters need it. These pipes connect to the main water supply and must be able to handle high water pressure. This pressure is vital for pushing water through hoses and up to the higher floors of buildings.

When a fire breaks out, firefighters can connect their hoses to the nearest hydrant. The pipes then deliver a strong, steady flow of water to help put out the flames. Without this system, firefighters would have a much harder time doing their job.

Identifying Common Issues with Fire Hydrant Pipes and their Consequences

Fire hydrant pipes, despite their crucial role in public safety, are not immune to problems. Understanding these issues is vital for maintaining an effective fire protection system. Let’s delve into the common problems that can affect fire hydrant pipes and explore their potential consequences.

Leaks:

Leaks are perhaps the most frequent issue with fire hydrant pipes. They can range from minor drips to major ruptures. Even small leaks shouldn’t be underestimated:

Water loss:

A seemingly insignificant leak can waste thousands of gallons of water over time, leading to higher water bills for the community.

Pressure reduction: Leaks can significantly decrease water pressure in the system. During a fire, this could mean the difference between containing a blaze quickly or allowing it to spread.

Environmental impact: Constant leaks can erode the soil around pipes, potentially leading to sinkholes or damage to nearby structures.

Contamination risk: Cracks that allow water out can also allow contaminants in, potentially compromising water quality.

Corrosion:

Most fire hydrant pipes are made of metal, making them susceptible to corrosion:

Weakened structure: Corrosion eats away at the pipe material, thinning the walls and making them more prone to breaks or collapse.

Reduced flow capacity: As pipes corrode, they become rougher inside. This increased friction can slow water flow, reducing the system’s overall effectiveness.

Water discoloration: Corrosion can cause rusty water, which might be harmless but can stain laundry and fixtures.

Hidden danger: Corrosion often starts from the inside of the pipe, making it difficult to detect until a major failure occurs.

Blockages:

Various materials can obstruct fire hydrant pipes:

Sediment buildup: Over time, mineral deposits can accumulate, narrowing the pipe’s diameter and restricting water flow.

Debris intrusion: During maintenance or repairs, dirt, rocks, or other debris might enter the system.

Biological growth: In some cases, algae or other organisms can grow inside pipes, especially in areas with low water flow.

Freezing: In cold climates, water left in pipes can freeze, creating ice blockages that can damage the system.

Aging Infrastructure:

Many cities have fire hydrant systems that are decades old:

Material fatigue: Older pipes may be made of outdated materials more prone to failure.

Joint failures: The connections between pipe sections can wear out over time, leading to leaks or separations.

Incompatibility issues: As systems are updated piecemeal, newer components might not work optimally with older parts.

External Damage:

Fire hydrant pipes can be damaged by outside forces:

Construction accidents: Excavation work can accidentally hit and rupture underground pipes.

Vehicle impacts: Cars or trucks might crash into above-ground hydrants, potentially damaging the connected pipes.

Ground shifts: Earthquakes or soil settlement can misalign or stress pipes.

Consequences of These Issues:

The problems outlined above can have serious repercussions:

- Reduced firefighting capability: When hydrants don’t deliver the expected water volume or pressure, it hampers firefighters’ ability to control blazes quickly.

- Increased property damage: Delays in getting water on a fire can lead to more extensive and costly damage to buildings and their contents.

- Risk to life safety: In worst-case scenarios, hydrant failures could put both firefighters and civilians in greater danger during a fire.

- Economic impact: Repairing major pipe failures can be extremely expensive and disruptive to communities.

- Water quality concerns: Compromised pipes can lead to contaminated water, potentially causing health issues.

Maintenance and Prevention:

Given these potential problems, regular maintenance is crucial:

- Routine inspections: Regular checks can catch issues early before they become critical.

- Flushing programs: Periodically flushing hydrants helps clear sediment and identifies potential problems.

- Cathodic protection: This technique can help prevent corrosion in metal pipes.

- Smart monitoring: Some cities are implementing sensors and data analytics to detect issues in real-time.

- Replacement programs: Proactively replacing aging infrastructure can prevent many problems before they start.

By understanding these common issues and their consequences, communities can better appreciate the importance of maintaining their fire hydrant pipe systems. Regular attention and investment in this critical infrastructure help ensure that when fires occur, the water will flow when and where it’s needed most.

Also Read: Ultimate Maintenance Checklist for Fire Hydrants: Ensuring Safety and Functionality

Regular Inspection and Maintenance: The Key to Reliable Fire Hydrant Pipes

Maintaining a reliable fire hydrant system is crucial for public safety. Regular inspection and maintenance of fire hydrant pipes are essential to ensure they function properly when needed most. Let’s explore the key aspects of keeping these vital systems in top condition.

Fire Hydrant Pipe Inspection:

Regular inspections are the foundation of a well-maintained fire hydrant system. These typically involve:

Visual checks: Inspectors look for signs of damage, corrosion, or leaks on visible parts of the system.

Underground surveys: Using specialized equipment, technicians can detect leaks or weaknesses in buried pipes without excavation.

Pressure testing: This involves checking if the hydrant can deliver water at the required pressure.

Flow testing: Measuring the water flow rate ensures the system can provide enough water during an emergency.

Valve inspections: All valves in the system are checked to ensure they open and close properly.

Inspections should be conducted at least annually, with more frequent checks in areas prone to issues or extreme weather conditions.

Fire Hydrant Pipe Testing:

Testing goes beyond visual inspections to ensure the system’s functionality:

Hydrostatic testing: Pipes are pressurized to check for leaks or weak points.

Water quality testing: Samples are analyzed to ensure the water meets safety standards.

Backflow prevention testing: This ensures contaminated water can’t flow back into the main supply.

Flushing tests: Running water through the system at high velocities helps clear sediment and identifies flow issues.

Fire Hydrant Pipe Repair:

When problems are identified, prompt repair is crucial:

Leak repairs: Small leaks might be fixed with specialized clamps or sealants, while larger ones may require pipe section replacement.

Joint repairs: Deteriorated joints can often be resealed or replaced without extensive excavation.

Valve repairs: Faulty valves are typically replaced to ensure reliable operation.

Corrosion treatment: For pipes with surface corrosion, cleaning and applying protective coatings can extend their lifespan.

Fire Hydrant Pipe Replacement:

Sometimes, repair isn’t enough, and pipes need to be replaced:

Trenchless methods: Technologies like pipe bursting or slip lining can replace pipes with minimal surface disruption.

Open-cut replacement: For severely damaged sections, traditional excavation and replacement may be necessary.

System upgrades: Older pipes might be replaced with newer materials that offer better performance and longevity.

Fire Hydrant Pipe Upkeep:

Ongoing maintenance helps prevent issues before they start:

Regular flushing: This removes sediment and helps maintain water quality.

Lubrication: Moving parts like valve stems need periodic lubrication to ensure smooth operation.

Painting: Keeping external parts well-painted protects against corrosion and makes hydrants more visible.

Winterization: In cold climates, pipes and hydrants need protection against freezing.

Vegetation control: Keeping the area around hydrants clear ensures easy access for firefighters.

Implementing a Maintenance Program:

An effective maintenance program includes:

Scheduling: Regular, planned inspections and maintenance activities.

Record-keeping: Detailed logs of all inspections, tests, and repairs.

Training: Ensuring maintenance staff are well-trained in the latest techniques.

Budgeting: Allocating sufficient funds for ongoing maintenance and necessary upgrades.

Public awareness: Educating the community about the importance of reporting damaged or leaking hydrants.

Technology in Maintenance:

Modern technology is improving fire hydrant maintenance:

GIS mapping: Digital maps help track the location and status of all system components.

Remote monitoring: Sensors can provide real-time data on system pressure and flow.

Predictive analytics: Using data to predict where and when issues are likely to occur.

Mobile apps: Field technicians can access and update information in real-time.

The Importance of Proactive Maintenance:

Reactive maintenance – fixing problems as they occur – is not enough for critical systems like fire hydrant pipes. A proactive approach that prevents issues before they become emergencies is essential. This not only ensures better fire protection but can also save money in the long run by avoiding costly emergency repairs and water loss.

By prioritizing regular inspection and maintenance of fire hydrant pipes, communities can ensure their fire protection systems remain reliable and ready to perform when lives and property are at stake. This commitment to upkeep is a crucial investment in public safety that pays dividends in peace of mind and emergency preparedness.

Also Read: Mastering Fire Hydrant Systems: A Comprehensive Guide for Fire Safety Officers

Upgrading Outdated Fire Hydrant Pipe Systems for Enhanced Fire Safety

As cities grow and infrastructure ages, upgrading fire hydrant pipe systems becomes crucial for maintaining and improving fire safety. This process involves replacing old, potentially unreliable pipes with modern, more efficient systems. Let’s explore the key aspects of this important undertaking.

Fire Hydrant Pipe Upgrade:

Upgrading fire hydrant pipes is a complex process that involves several steps:

Assessment: Engineers evaluate the current system, identifying weaknesses and areas for improvement.

Planning: A comprehensive plan is developed, considering factors like water demand, pressure requirements, and future growth.

Material selection: Modern materials like ductile iron or high-density polyethylene (HDPE) are chosen for their durability and performance.

Capacity increase: Larger diameter pipes may be installed to improve water flow and pressure.

Smart technology integration: New systems often include sensors and monitoring devices for real-time performance tracking.

Fire Hydrant Pipe Modernization:

Modernization goes beyond simple replacement, incorporating new technologies and design principles:

Pressure management: Advanced pressure reducing valves help maintain optimal system pressure.

Corrosion protection: Cathodic protection systems and protective coatings extend pipe lifespan.

Seismic resilience: In earthquake-prone areas, flexible joints and pipe materials are used to withstand ground movement.

Water quality improvements: Modern pipe materials and linings help maintain water purity.

Energy efficiency: Improved system design can reduce pumping costs and energy usage.

Fire Hydrant Pipe Replacement Project:

Large-scale replacement projects require careful planning and execution:

Phasing: Work is typically done in stages to minimize disruption to fire protection and water service.

Traffic management: Plans are made to manage road closures and detours during construction.

Public communication: Keeping residents informed about the project’s progress and any service interruptions.

Coordination: Working with other utilities to avoid conflicts and potentially combine projects.

Environmental considerations: Implementing erosion control and other measures to protect the environment during construction.

Fire Hydrant Pipe Installation:

Installing new fire hydrant pipes involves several key steps:

Excavation: Digging trenches to access the installation area.

Bedding: Preparing a stable base for the new pipes.

Pipe laying: Carefully placing and aligning the new pipes.

Joining: Connecting pipe sections using appropriate methods (e.g., welding, mechanical joints).

Testing: Pressure testing the new installation to ensure integrity.

Backfilling: Carefully covering the new pipes and restoring the surface.

Fire Hydrant Pipe Retrofit:

In some cases, full replacement isn’t necessary, and retrofitting can improve system performance:

Pipe lining: Applying internal coatings to improve flow and prevent corrosion.

Joint sealing: Addressing leaks at pipe joints without full pipe replacement.

Valve upgrades: Installing modern valves for better control and reliability.

Hydrant upgrades: Replacing old hydrants with newer, more efficient models.

Adding connection points: Installing additional hydrants or connection points to improve coverage.

Benefits of Upgrading:

- Improved reliability: Modern systems are less prone to failures and leaks.

- Enhanced fire protection: Better flow rates and pressure improve firefighting capabilities.

- Water conservation: Reducing leaks and improving efficiency saves water.

- Cost savings: While initially expensive, upgrades can reduce long-term maintenance and repair costs.

- Improved water quality: New pipes and materials can help maintain water purity.

Challenges in Upgrading:

- Cost: Pipe replacement projects are often expensive, requiring careful budgeting and potentially seeking grants or loans.

- Disruption: Construction can cause temporary inconveniences for residents and businesses.

- Complexity: Working around existing utilities and infrastructure can be challenging.

- Time: Large-scale upgrades can take months or even years to complete.

Innovative Approaches:

- Trenchless technologies: Methods like pipe bursting or slip lining can replace pipes with minimal surface disruption.

- 3D mapping: Advanced surveying techniques create detailed underground maps for better planning.

- Predictive modeling: Computer simulations help optimize system design and predict future needs.

- Green infrastructure: Some cities are incorporating sustainable drainage systems to complement traditional pipe networks.

Community Involvement:

Successful upgrade projects often involve the community:

Public meetings: Gathering input and addressing concerns before and during the project.

Education programs: Helping residents understand the importance of the upgrade.

Progress updates: Regular communications about project milestones and upcoming work.

Collaboration with local businesses: Minimizing disruption to commercial areas during construction.

Long-term Planning:

Upgrading fire hydrant pipe systems isn’t a one-time event. It requires ongoing commitment:

Master planning: Developing long-term strategies for system maintenance and improvement.

Regular reassessment: Continually evaluating system performance and emerging technologies.

Budgeting: Setting aside funds for future upgrades and maintenance.

Training: Ensuring personnel are familiar with new technologies and maintenance requirements.

Upgrading outdated fire hydrant pipe systems is a critical investment in community safety and infrastructure reliability. While it presents challenges, the benefits in terms of improved fire protection, water conservation, and long-term cost savings make it an essential undertaking for growing and evolving communities.

By embracing modern materials, technologies, and design principles, cities can ensure their fire protection systems are ready to meet both current needs and future challenges.

Also Read: Comprehensive Guide to Fire Fighting Equipment and Systems for Building Safety

Ensuring Compliance and Optimizing Fire Hydrant Pipe Performance

To maintain effective fire protection systems, it’s crucial to adhere to regulations, follow industry standards, and implement best practices. This approach not only ensures legal compliance but also optimizes the performance of fire hydrant pipes. Let’s explore the key aspects of this important topic.

Fire Hydrant Pipe Regulations:

Regulations governing fire hydrant pipes vary by location but typically cover several key areas:

- Installation requirements: Specifying minimum pipe diameters, materials, and installation methods.

- Pressure standards: Mandating minimum and maximum pressure levels for the system.

- Flow rates: Establishing required water flow rates based on the area’s fire risk assessment.

- Hydrant spacing: Dictating the maximum distance between hydrants in different zones.

- Inspection frequency: Setting mandatory schedules for system inspections and testing.

- Water quality: Ensuring that water in the system meets safety and purity standards.

- Accessibility: Requiring clear access to hydrants for fire department use.

Key regulatory bodies often include:

- National Fire Protection Association (NFPA)

- American Water Works Association (AWWA)

- Local fire departments and water authorities

- State and federal environmental agencies

Staying up-to-date with these regulations is crucial, as non-compliance can result in fines, increased liability, and compromised fire protection.

Fire Hydrant Pipe Standards:

Industry standards provide detailed guidelines for system design, installation, and maintenance:

- Material standards: Specifications for pipe materials, fittings, and valves.

- Design standards: Guidelines for system layout, hydraulic calculations, and capacity planning.

- Testing standards: Procedures for pressure testing, flow testing, and water quality analysis.

- Maintenance standards: Recommended practices for system upkeep and repair.

- Documentation standards: Requirements for record-keeping and system mapping.

Key standard-setting organizations include:

- American National Standards Institute (ANSI)

- ASTM International

- International Organization for Standardization (ISO)

Adhering to these standards ensures system reliability and interoperability with firefighting equipment.

Fire Hydrant Pipe Best Practices:

Beyond regulations and standards, industry best practices can further enhance system performance:

- Regular flushing: Periodic system flushing removes sediment and helps maintain water quality.

- Preventive maintenance: Scheduled checks and maintenance prevent minor issues from becoming major problems.

- Corrosion prevention: Implementing cathodic protection and using corrosion-resistant materials.

- Smart system integration: Utilizing sensors and data analytics for real-time monitoring.

- Training programs: Ensuring maintenance personnel are well-trained in the latest techniques.

- Public awareness: Educating the community about hydrant importance and reporting issues.

- Coordination with fire departments: Regular joint exercises and system familiarization.

- Winter preparations: In cold climates, taking steps to prevent freezing and ensure year-round operability.

Fire Hydrant Pipe Efficiency:

Optimizing system efficiency can improve performance and reduce operational costs:

- Hydraulic modeling: Using computer simulations to optimize system design and operation.

- Pressure management: Implementing pressure reducing valves to maintain optimal system pressure.

- Leak detection: Utilizing acoustic sensors and other technologies to quickly identify and address leaks.

- Energy-efficient pumps: Installing and maintaining high-efficiency pumping systems.

- Water conservation: Implementing strategies to minimize water waste during testing and maintenance.

- Asset management: Using data-driven approaches to prioritize maintenance and replacement activities.

- Trenchless technologies: Employing modern pipe rehabilitation methods to minimize disruption and costs.

Fire Hydrant Pipe Performance Metrics:

Key performance indicators help assess and improve system effectiveness:

- Flow rate: Measuring the volume of water delivered per minute at various points in the system.

- Static pressure: The pressure in the system when water is not flowing.

- Residual pressure: The pressure maintained in the system during maximum demand.

- Water quality parameters: Monitoring factors like chlorine levels, pH, and turbidity.

- Response time: How quickly the system can deliver required water volume after hydrant activation.

- Reliability index: Tracking the frequency and duration of system outages or failures.

- Maintenance efficiency: Measuring the time and resources required for system upkeep.

- Water loss ratio: Calculating the difference between water input and authorized consumption.

Implementing Performance Monitoring:

- SCADA systems: Supervisory Control and Data Acquisition systems for real-time monitoring.

- Regular testing: Conducting flow tests and pressure checks at scheduled intervals.

- Data logging: Maintaining detailed records of system performance and maintenance activities.

- Benchmarking: Comparing system performance against industry standards and similar municipalities.

- Annual reviews: Conducting comprehensive system evaluations to identify areas for improvement.

Challenges in Compliance and Optimization:

- Aging infrastructure: Older systems may struggle to meet modern standards without significant upgrades.

- Budget constraints: Balancing the need for system improvements with financial limitations.

- Evolving regulations: Keeping up with changing rules and standards can be challenging.

- Technical complexity: Modern systems require specialized knowledge to maintain and optimize.

- Coordination: Aligning the efforts of water departments, fire services, and other stakeholders.

Future Trends:

- IoT integration: Increasing use of Internet of Things devices for system monitoring and control.

- AI and machine learning: Employing artificial intelligence for predictive maintenance and system optimization.

- Sustainable materials: Developing and adopting more environmentally friendly pipe materials.

- Climate resilience: Designing systems to withstand increasing environmental stresses due to climate change.

- Integration with smart city initiatives: Coordinating fire protection systems with broader urban management efforts.

Ensuring compliance and optimizing performance of fire hydrant pipe systems is an ongoing process that requires dedication, expertise, and resources. By adhering to regulations, following industry standards, implementing best practices, and focusing on efficiency and performance metrics, municipalities can create robust, reliable fire protection systems.

This not only ensures legal compliance but also provides the highest level of safety for the community. As technology and best practices continue to evolve, staying informed and adaptable will be key to maintaining effective fire hydrant pipe systems in the future.

3 thoughts on “Ensuring Fire Safety : The Importance of Properly Maintained Fire Hydrant Pipes”

Pingback: There was a fire in a house in, Vikaspuri fire incident

Pingback: kerala Fire Incident at Pappanamcode Insurance Office

Pingback: Kamala Mills Fire: Major Mumbai Fire Incident at Times Tower

Comments are closed.