Understanding the Basics of Fire Hydrant Systems

A fire hydrant is a critical piece of fire protection equipment that provides a source of water to help extinguish fires. Fire hydrants are connected to underground water supply pipes and are strategically placed throughout communities and cities.

A typical fire hydrant system consists of several key components:

- Barrel – This is the vertical cast iron cylinder that extends from the underground pipe up to the surface.

- Valve – Located at the base, this valve controls the flow of water from the underground supply line into the hydrant.

- Outlet Nozzles – Most hydrants have two or three outlet nozzles where fire hoses can be connected to access the water supply.

- Operating Nut – This large nut on the top enables firefighters to open or close the drain valve to allow water in or release pressure.

There are several common types of fire hydrants found throughout the United States:

- Dry Barrel Hydrants are the most common, unsuitable for areas with freezing temperatures as the barrel is empty until water pressure builds.

- Wet Barrel Hydrants have water in the barrel at all times, making them suitable for cold climates.

- Wall Hydrants extend out from the sides of buildings rather than up from the ground.

The primary function of any fire hydrant is to provide an instant, reliable source of water that allows firefighters to quickly extinguish or contain fires before they spread uncontrollably. Proper hydrant maintenance and adherence to hydrant color coding standards are crucial for community fire safety.

Key Components of a Fire Hydrant System

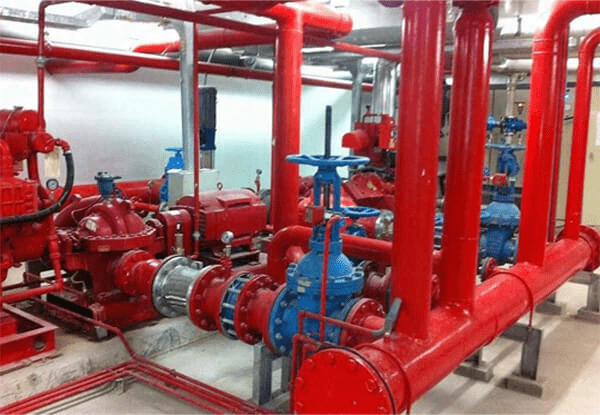

A complete fire hydrant system consists of several vital components that enable it to effectively deliver water for firefighting purposes. The key components include:

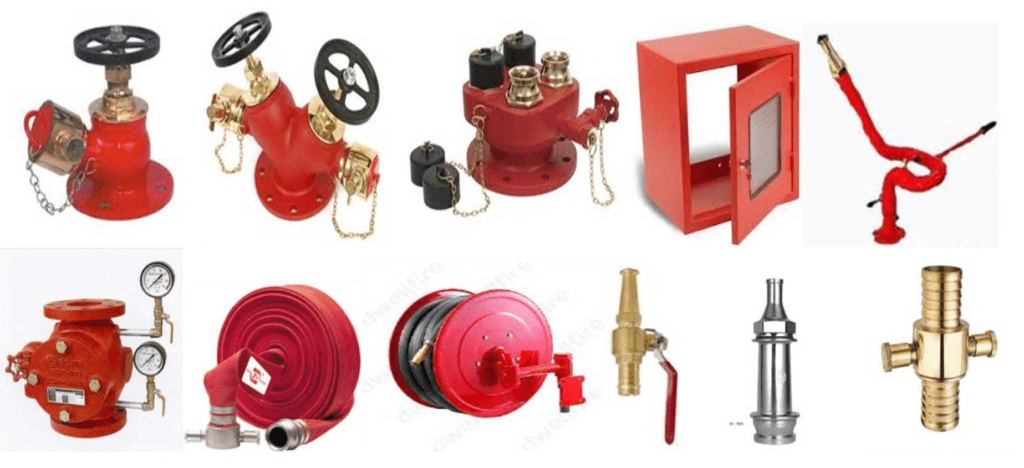

Fire Hydrant Hose Reel

This is a portable fire hose that can be quickly attached to the hydrant nozzle outlet. Hose reels allow firefighters to rapidly deploy hoses over short distances from the hydrant to the fire.

Dry Barrel Fire Hydrant

The most common type, dry barrel hydrants have an underground vertical pipe connected to the water supply main, with a valve at the base. The barrel portion above ground remains dry until water pressure builds when the hydrant is opened.

Wet Barrel Fire Hydrant

These hydrants have the underground pipe and barrel constantly filled with water, making them suited for areas with freezing temperatures. A valve drain is used to evacuate the water after use.

Fire Hydrant Nozzle

The outlet nozzle(s) on the hydrant allow connection points to attach a fire hose. Most hydrants have between 2-3 nozzles with thread sizes like 2.5″ or 4.5″ in diameter.

Fire Hydrant Monitor

A monitor is a water cannon device that can be mounted atop a hydrant to provide a high-powered water stream over long distances. Monitors are useful for dousing large or remote fires.

Each component plays an important role in the fire hydrant’s ability to funnel water from the main supply line and disperse it effectively through hoses and monitors during emergencies.

Selecting the Right Fire Hydrant System for Your Needs

With different types and configurations of fire hydrants available, it’s important to select the right system for your facility’s specific requirements. Here are some key factors to consider:

Fire Hydrant Types

The two main types are wet barrel and dry barrel hydrants. Wet barrels have water in the barrel at all times, making them ideal for areas with freezing temperatures. Dry barrels are more common and less expensive, but unsuitable for areas that experience freezing.

Fire Hydrant Size

Hydrant sizes like 4 inch, 5 inch, and 6 inch refer to the diameter of the connection between the hydrant and the underground water supply line. Larger sizes provide higher water flow capabilities.

Fire Hydrant Flow Rate

The required flow rate (typically measured in gallons per minute) depends on the fire hazard level and size of the area being protected. High-risk facilities like hospitals require higher flow rates.

Fire Hydrant Water Pressure

Most hydrants require a minimum water pressure of 20 psi to work effectively. Identifying the existing or planned water supply pressure is crucial for hydrant performance.

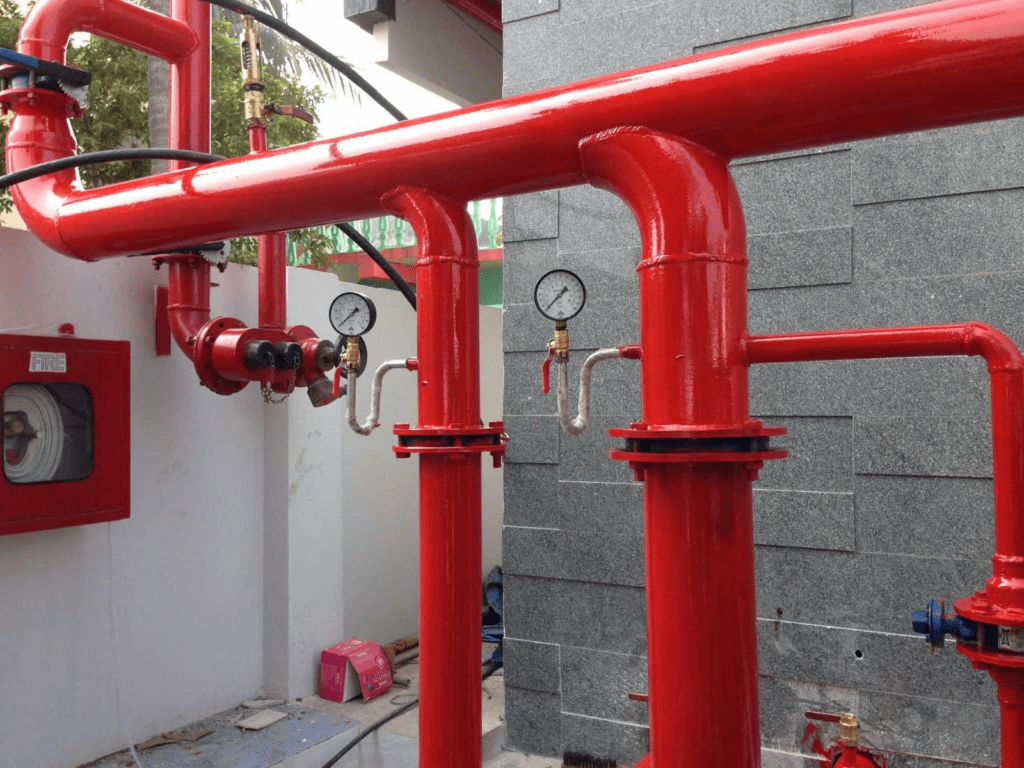

Fire Hydrant Installation

Proper installation following NFPA codes is vital, including requirements for hydrant spacing, distribution around buildings/risks, and ensuring pits/barrels drain adequately after use.

By carefully evaluating your fire risk level, water supply details, climate conditions, and code requirements, you can select hydrants with the appropriate type, size, flow rate and pressure capabilities to ensure effective fire protection for your facility.

Maintaining and Inspecting Fire Hydrant Systems

Proper maintenance and inspection of fire hydrant systems is crucial to ensure they will operate reliably during an emergency. Here are some key aspects of hydrant upkeep:

Fire Hydrant Maintenance

Regular maintenance should include lubricating operating nuts, inspecting and replacing worn parts, tightening flange bolts, and clearing debris from outlets. Dry barrel hydrants need to have interior surfaces cleaned and lubricated.

Fire Hydrant Inspection

Hydrants should undergo frequent inspections to check for leaks, damages, obstructions or accessibility issues. Inspectors verify operating nuts can open/close properly and look for any painting/remarking needs.

Fire Hydrant Testing

Periodic flow testing is necessary to confirm each hydrant can deliver its expected water flow rate and pressure. This hydrant flushing process verifies adequate performance.

Fire Hydrant Repair

Any hydrants found to be leaking, damaged or not operating correctly during inspection/testing require prompt repair or replacement to restore proper working condition.

Fire Hydrant Winterization

In cold climates, winterization procedures like pumping out water and lubricating interior surfaces prevent freezing damage during winter months when hydrants are unlikely to be used.

Sticking to a routine maintenance, inspection, testing and repair schedule based on NFPA codes helps ensure fire hydrant systems remain compliant and ready to dependably provide lifesaving fire protection water supply when needed.

Integrating Fire Hydrant Systems with Other Fire Safety Measures

A comprehensive fire safety strategy requires integrating fire hydrant systems with other critical fire protection measures. Key areas of integration include:

Fire Sprinkler Systems

Fire hydrants provide the water supply that allows building sprinkler systems to function properly. Calculating required flow rates and pressures from hydrants is vital when designing sprinkler system hydraulics.

Fire Alarm Systems

Hydrant locations should be included on facility premise maps and tied into fire alarm monitoring systems. This enables responding firefighters to quickly identify the nearest operable hydrants.

Fire Extinguishers

Portable extinguishers serve as a first response in containing small fires, buying time until hose lines can be deployed from nearby hydrants. Training covers use of both extinguishers and hydrants.

Fire Safety Plan

An integrated emergency action plan must account for hydrant locations, required hose routing, managing connections, and establishing incident command areas relative to hydrant positioning.

Fire Safety Training

Personnel should be trained on hydrant operation protocols like removing caps, attaching hoses, communicating with the pump operator, and hydrant marking/color coding.

By properly integrating hydrants within a multi-faceted fire protection plan involvingsprinklers, alarms, equipment, procedures and training, facilities can optimize their fire safety preparedness and emergency response capabilities.

Reliable fire hydrant systems are vital for ensuring fire safety and protection. Proper installation, maintenance, and integration with other fire safety measures are essential. With well-designed and regularly inspected hydrants, communities can rapidly access water supplies to control fires and save lives.

2 thoughts on “Mastering Fire Hydrant Systems: A Comprehensive Guide for Fire Safety Officers”

Pingback: Understanding Fire Protection System: Types, Components, and Maintenance

Pingback: Comprehensive Guide to Fire Alarm Systems: Types, Addressable Systems, and Testing - Basic Elements

Comments are closed.